The main reasons for choosing stainless steel coils in modern manufacturing

When it comes to industrial excellence and reliability, few materials are comparable to the versatility and performance of stainless steel coils. These premium steel coils are designed to meet the rigorous needs of industries from automotive to construction and home appliance production. Stainless steel coils are the backbone of modern manufacturing processes with precise design and providing a mixture of strength and durability.

One of the key features of these stainless steel coils is their significant resistance to corrosion. This is a crucial property that ensures longevity even in harsh environments. Whether exposed to moisture, chemicals or extreme temperatures, stainless steel coils maintain their integrity, making it the material of choice for applications requiring reliability and endurance. Their adaptability to cutting, bending and manufacturing processes further emphasizes their importance in modern engineering.

Decode the anatomical structure of stainless steel coils

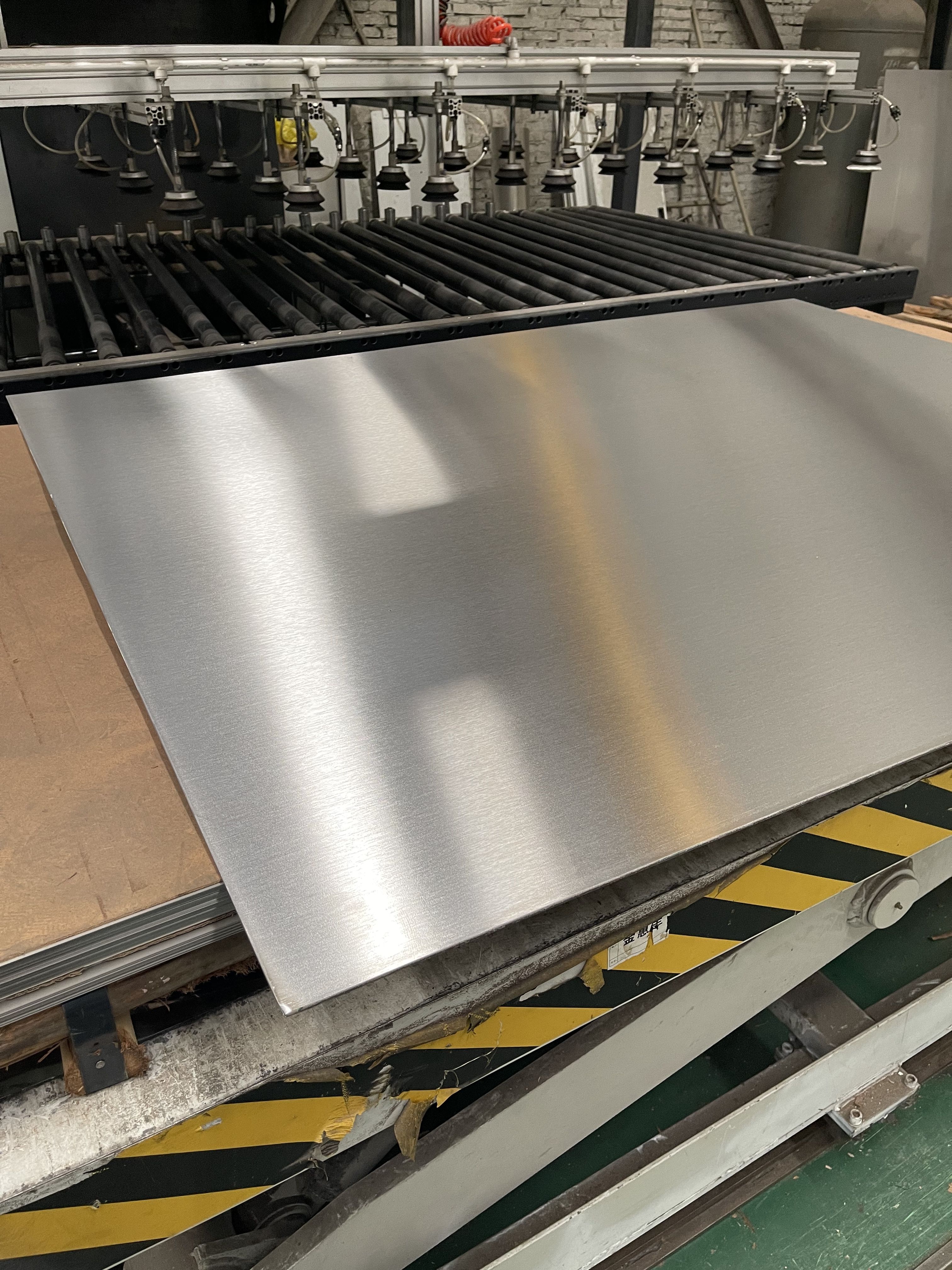

Before delving into its application, it is necessary to understand what makes stainless steel coils so excellent. First, these coils are manufactured using state-of-the-art technologies of priority accuracy and uniformity. Their mirror-like reflections are more than just an aesthetic function, they are carefully designed indicators that begin with the smelting process and continue with careful rolling. The uniform thickness of these coils ensures consistent performance, making them ideal for a variety of industrial uses.

Another noteworthy feature of stainless steel coils is their high tensile strength. This makes them ideal for demanding applications where materials require them to withstand heavy loads and pressures. Furthermore, coils are designed to meet stringent industry standards to ensure that they not only perform well, but also improve the overall quality of the final product.

Application of cross-industry stainless steel coils

The utility of stainless steel coils extends to many industries, each taking advantage of its unique characteristics. Here are some notable applications:

1. **Automotive Industry**: Stainless steel coils are widely used in the production of exhaust systems, engine components and structural frames. Their strength and corrosion resistance make them ideal for environmental conditions that vehicles face daily.

2. **Architecture Area**: Due to their durability and striking appearance, stainless steel coils are the material of choice for modern architectural design. From cladding and roofing to structural components, their versatility and longevity are invaluable in construction projects.

3. **Home Appliances**: The reflective effect of stainless steel coils adds a little elegance to household equipment such as refrigerators, ovens and dishwashers. In addition to aesthetics, the material's ability to resist corrosion and withstand high temperatures ensures long-lasting performance.

4. **Food and Beverage Industry**: Stainless steel is the undisputed choice for food-grade applications. These coils are used to make storage tanks, kitchen counters and food processing equipment because their surfaces do not react and clean.

5. **Medical Area**: The biocompatibility and corrosion resistance of stainless steel make it suitable for surgical instruments, medical equipment and hospital furniture. The accuracy and cleanliness of stainless steel coils provide make them reliable in a strict medical environment.

Sustainability Edge: Stainless Steel Coil

In today's environmentally conscious era, the sustainability of stainless steel cannot be ignored. One of the outstanding features of stainless steel coils is their recyclability. They can be recycled endlessly without losing their property, making them an environmentally friendly option for industries looking to reduce their carbon footprint.

In addition, the production of stainless steel is increasingly integrated with energy-saving methods. From the manufacturing process to the end of the life cycle, stainless steel is consistent with modern environmental standards. Companies embrace these coils not only for their outstanding performance, but also because of their role in promoting sustainable practices.

Note details: storage and processing

Apart from manufacturing, it is commendable for attention to the details of storing and handling stainless steel coils. The coils are located in a carefully organized warehouse equipped with advanced processing systems to ensure they remain in their original condition. Fascinated in transport and placed on a solid wooden euro pallet, all aspects of their storage emphasize their importance in modern engineering and construction.

This careful treatment ensures that the coil reaches your facility in perfect condition and is ready to transform into an innovative solution. Whether you are making automotive components or designing cutting-edge buildings, you can be confident in the quality and reliability of these stainless steel coils.

Why is the backbone of progress

Accuracy, durability and adaptability are just some of the qualities that define the stainless steel coils. Their excellent corrosion resistance, tensile strength and visual appeal make them ideal for a variety of applications. Whether you are cutting, shaping or stamping, these coils offer unparalleled performance while maintaining their structural integrity.

In addition, today's manufacturers need to provide materials that are functional and consistent with environmental sustainability. Stainless steel can inspect two boxes by combining extraordinary functionality with a commitment to environmental practice. From automotive workshops to medical facilities, stainless steel coils enable the industry to drive boundaries and innovation, never before.

If you want to cheer for the next wave of innovation in your industry, stainless steel coils are an investment that ensures great results. With their perfect balance of form and function, they really represent the future of industrial excellence.