Introduction to stainless steel coils

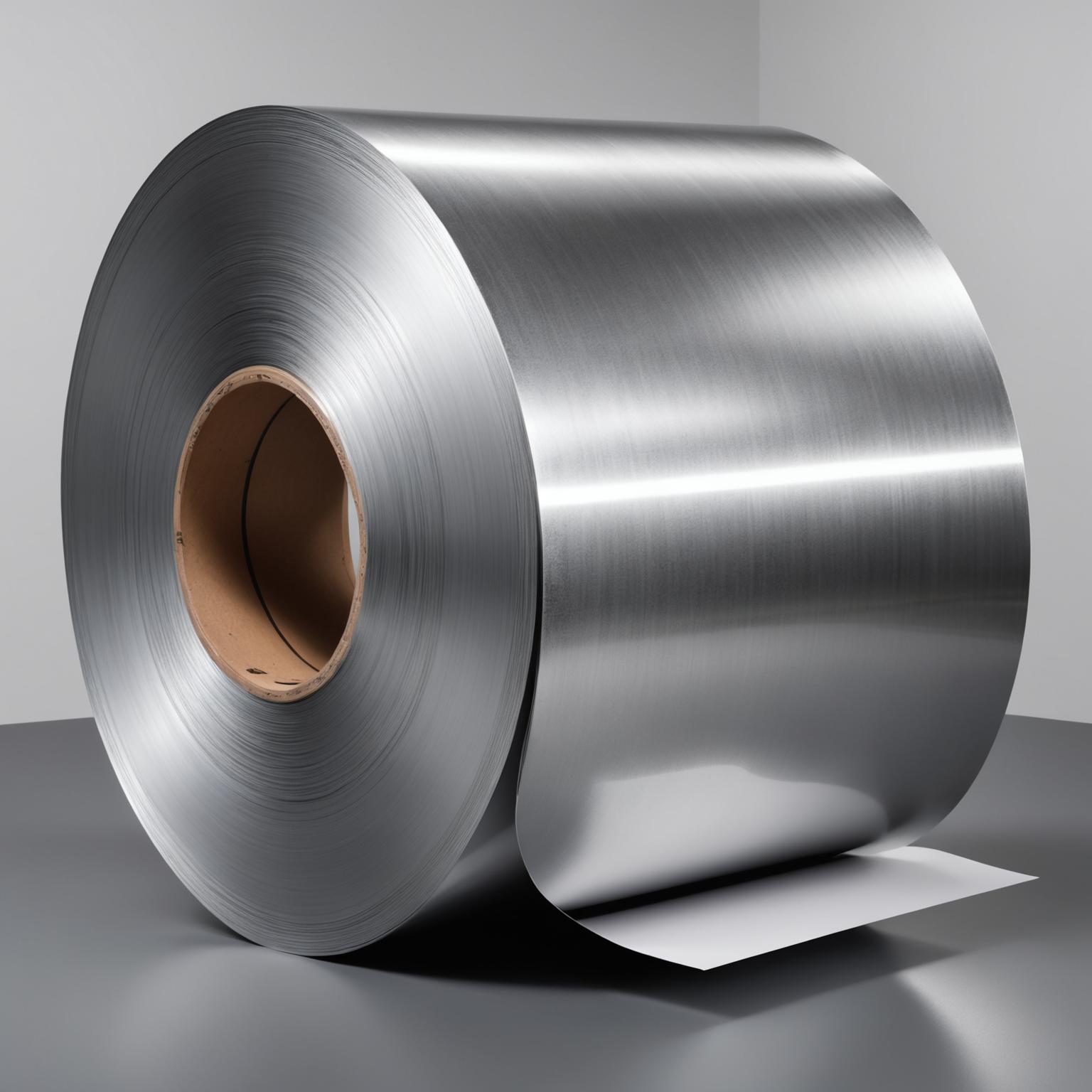

From construction to automobiles and consumer goods, stainless steel coils have become one of the wide range of industries and most popular materials. These coils represent a perfect blend of durability, complexity, and high-performance utilities, making them an advanced choice for businesses and manufacturers that demand excellence in their projects. Stainless steel coils pave the way for innovation with their corrosion resistance, aesthetic appeal and recyclability while ensuring sustainability.

One of the main advantages of stainless steel coils is their adaptability to a variety of applications. Whether you need precise engineering for high-voltage environments or enhanced surface appeal for consumer-facing designs, stainless steel coils offer impeccable quality and reliability. This guide explores how to make the most of stainless steel coils, including their benefits, uses and practical applications.

Why choose stainless steel coils?

Stainless steel coils are designed to withstand time-testing, with special corrosion and damage resistance. These coils are made of highly stainless steel and have properties that stand out from other materials. One of the key features is their excellent mirror finish, which combines functionality with artistic quality, making it ideal for areas that are important for performance and aesthetics.

The inherent strength of stainless steel coils ensures that they are suitable for demanding applications. Whether in architectural design, automotive components or cutting-edge equipment, these materials retain their form and function even in the harshest environmental conditions. Additionally, stainless steel is fully recyclable, making these coils an environmentally friendly option for manufacturers designed to reduce their carbon footprint.

Application of stainless steel coils

Stainless steel coils are used for a wide range of purposes according to specific industry requirements. Here are some key areas of their application:

1. **Architectural Design**: Stainless steel coils play an important role in creating sustainable and visually striking architectural designs. Their polished shiny surfaces provide an ideal modern look for curtain walls, roofing solutions and building exteriors. Corrosion resistance and durability, they ensure long-lasting performance.

2. **Auto Industry**: In the automotive industry, these coils are used to manufacture various components such as exhaust pipes, decorative and decorative elements. Their heat resistance and excellent ductility make them suitable for creating lightweight but powerful parts.

3. **Consumer Products**: Stainless steel coils are indispensable in the production of high-end electrical appliances and other consumer products. Their attractive appearance enhances the appearance of the product while ensuring long-term quality performance.

4. **Industrial Applications**: With seamless shaping, welds and mold capabilities, stainless steel coils are ideal for industrial manufacturing processes. They are used in chemical plants, food processing fields, and other high-pressure environments that require quality reliability.

Technical functions of stainless steel coils

While it is undeniable, while the aesthetic appeal of stainless steel coils is undeniable, their technical excellence is equally important. These coils are made with strict accuracy and tailor-made thickness to meet specific requirements.

1. **Corrosion Resistance**: One of the excellent features of stainless steel coils is their ability to resist corrosion, making them the first choice for water contact applications and harsh environments.

2. **Adaptive**: These coils can be cut, stamped and embossed to suit a variety of manufacturing processes without damaging the integrity of the material. Heat resistance and excellent ductility make it suitable for shaping complex designs.

3. **Ecologically Aware Manufacturing**: Stainless steel coils are 100% recyclable, emphasizing their role in sustainable development. Recyclability ensures that manufacturers and designers can cater to eco-conscious consumers while maintaining performance standards.

4. **Consistency**: Stainless steel coils maintain consistent width, thickness and tensile strength, ensuring easy handling and reliable performance in different applications.

How to maximize the effectiveness of stainless steel coils

Using stainless steel coils to achieve their full potential requires understanding of their technical functions and appropriate treatment methods. To optimize its utility, consider the following tips:

1. **Select the right grade**: Stainless steel coils have various achievements, and each steel pipe is suitable for a specific application. For example, 304 stainless steel is ideal for general applications, while 316 stainless steel provides additional resistance to corrosion in marine environments.

2. **Tailed sizes to your needs**: Manufacturers usually offer coils with customized thickness and size. It is important to view your project requirements to ensure that the materials fit seamlessly into your application.

3. **Investment Quality Handling**: Whether you are cutting, welding or forming, advanced technology is used to preserve the mirror finish and structural integrity of the coil during the manufacturing process.

4. **Focus on maintenance**: Although stainless steel is durable, regular cleaning and inspection ensures its sheen and performance remain intact over time.

Conclusion: Innovation is in line with excellence

The high-quality stainless steel coil is not only a roll of metal. This is an innovative solution designed to drive creativity and advance the entire industry. With its impeccable finish, corrosion resistance and environmentally friendly, the product sets new benchmarks for durability and functionality.

From achieving architectural excellence to changing automotive designs, stainless steel coils can redefine industry standards and consumer expectations. By prioritizing sustainability and superior technology, they have become the material of choice for visionaries who need style and substance.

As the industry develops, the role of multifunctional materials such as stainless steel coils will become even more indispensable in shaping the future. For builders, designers and manufacturers, investing in quality stainless steel coils is investing in innovation, reliability and long-lasting performance.