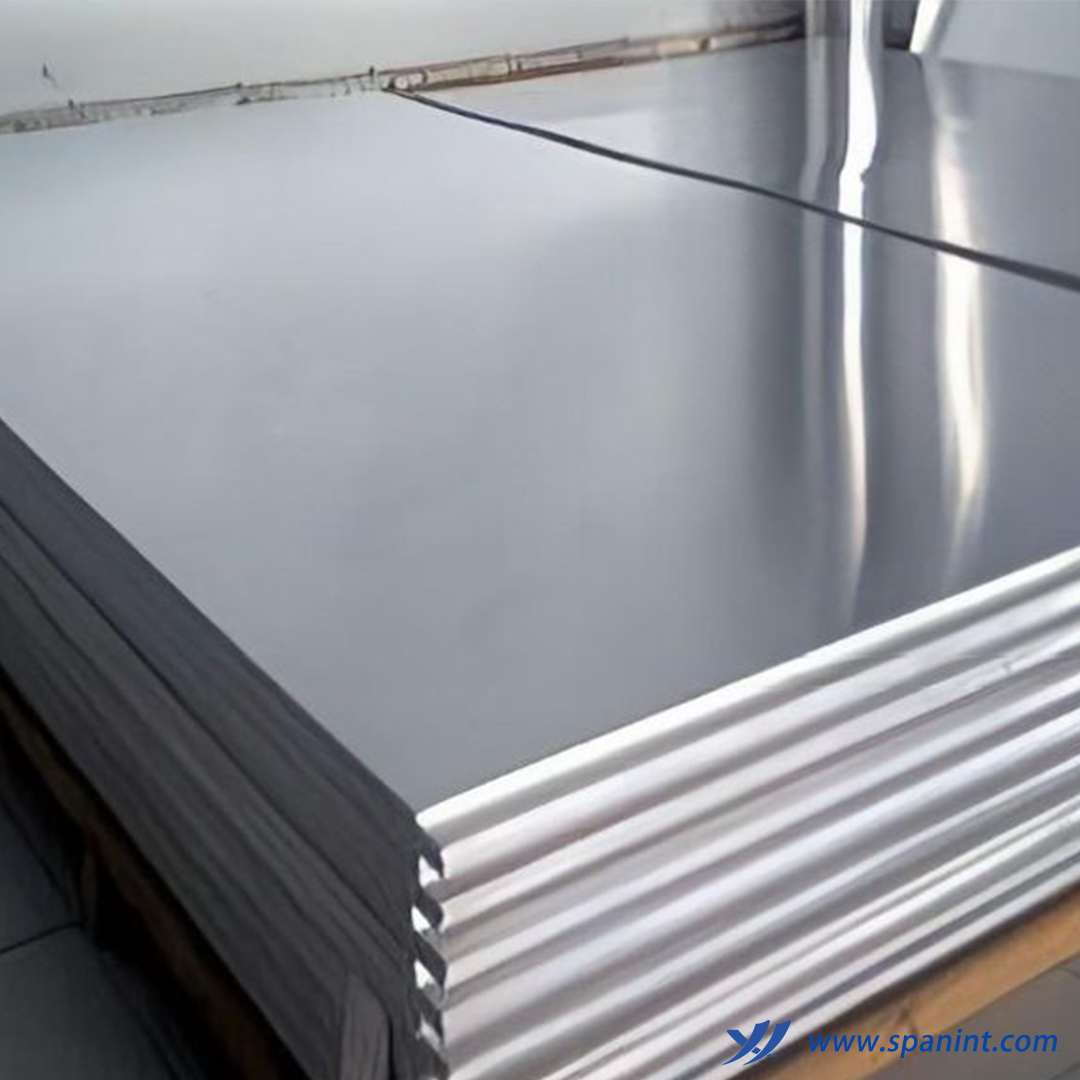

1. 304L stainless steel plate: the best choice for food storage tanks

1. 304L vs. 304: Key Difference

| Features | 304L stainless steel plate (UNS S30403) | Ordinary 304 stainless steel plate (UNS S30400) |

|---|---|---|

| Carbon content (C) | ≤0.03% | ≤0.08% |

| Intergranular corrosion resistance | Extremely excellent (stable after welding) | May weaken after welding |

| Applicable Standards | FDA, EU 10/2011, 3A | General Industrial Uses |

Why does the food industry choose 304L?

-

Low carbon content (≤0.03%): Reduce the precipitation of carbides in the welding heat-affected zone and avoid intergranular corrosion. It is especially suitable for CIP (in-situ cleaning) systems.

-

Higher acid and alkali resistance: Suitable for storage of acidic or alkaline media such as juice, dairy products, beer, etc.

2. Core advantages of Span International's 304L stainless steel plate

-

Ultra-low impurity control (S≤0.015%, P≤0.045%) → Reduce the risk of welding cracks

-

2B/BA surface treatment (Ra≤0.8μm) → Reduce bacterial attachment and comply with hygiene standards

-

Electrolytic polishing (EP) optional→ Enhance corrosion resistance and extend service life

2. How does Span International ensure the quality of food-grade 304L stainless steel plates?

1. Strict production standards

-

Material Traceability: Each batch of 304L stainless steel plates provides MTC (Material Test Certificate), including component analysis, mechanical properties and other data.

-

Complied with international certification:

✅ FDA 21 CFR 175.300 (US Food Contact Materials Standard)

✅ EU 10/2011 (EU Food Grade Stainless Steel Regulation)

✅ 3A Sanitary Standard (Dairy and Beverage Industry Certification)

2. Optimized processing performance

-

Excellent welding properties: Low carbon content reduces the corrosion risk of welding heat-affected zones, and is suitable for TIG, MIG, and laser welding.

-

High Forming: Suitable for deep-draining, rolling plates and other processing methods to ensure the accuracy of storage tank manufacturing.

3. Sustainability and Environmental Protection

-

100% recyclable, in line with the trend of green manufacturing

-

Reduce life cycle carbon emissions by 50% compared to plastic or fiberglass storage tanks

3. Practical application cases

1. Dairy storage tank

-

Material: Span International 304L stainless steel plate (thickness 3mm)

-

Application: 50-ton milk storage tank

-

Advantages:

-

Zero corrosion

under acidic environment of pH 4.2 -

Intergranular corrosion by CIP high temperature cleaning (80℃)

-

The service life is over 15 years

-

2. Beer fermentation tank

-

Material: Span 304L (2B surface + electrolytic polishing)

-

Advantages:

-

Resistant to tartaric acid crystal corrosion

-

Complied with 3A hygiene standards to ensure beer purity

4. Why choose Span International's 304L stainless steel plate?

-

Strict quality control: Monitor the entire process from smelting to rolling to ensure low impurities and high purity.

-

Global Supply Chain Support: Fast delivery to meet urgent needs.

-

Technical Support: Provide professional guidance on welding parameters, anti-corrosion plans, etc.

-

Cost Optimization: Large-scale production to reduce customer procurement costs.

Conclusion

The material of the food storage tank directly affects the product safety, operating costs and brand reputation. Span International's 304L stainless steel plate has become the first choice material for the global food industry with its low carbon content, international certification and excellent corrosion resistance.

📞 Contact us now to get samples or technical consultation:

-

Email:info@spanint.com

-

Tel:+98 912 8999161 +86 191 2044 0914 +86 137 9402 7696

- Website:spanint.com

-

-

-

-