When purchasing stainless steel round bars, it's essential to make informed decisions to ensure you select the right product for your project. These bars are widely used in construction, machinery, and manufacturing due to their durability and resistance to corrosion, but overlooking key aspects can lead to costly mistakes. This guide will walk you through the important factors to consider, helping you navigate the buying process with confidence and achieve optimal results for your applications.

Understanding the Material Quality

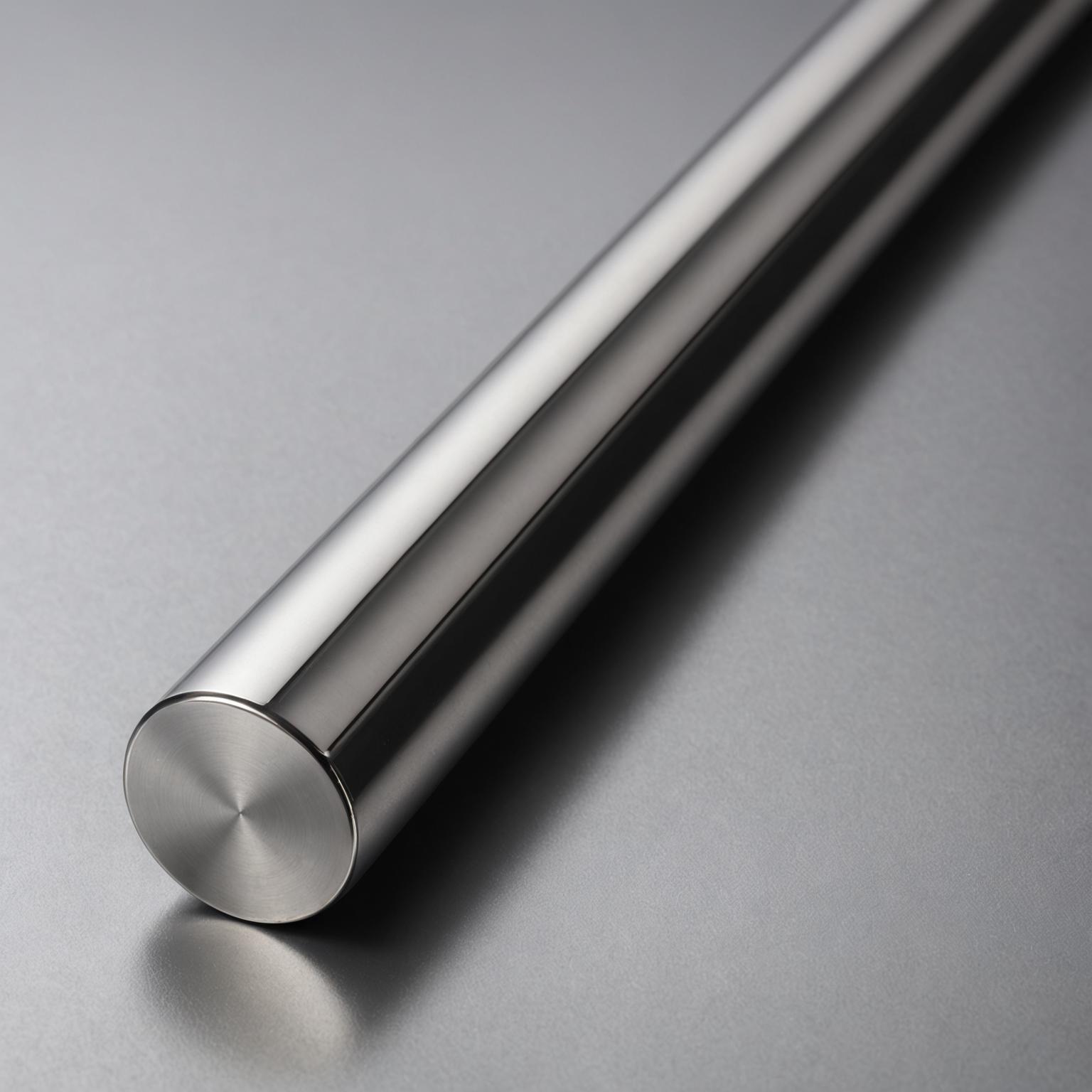

One of the primary things to note when purchasing stainless steel round bars is the quality of the material itself. Stainless steel round bars come in various grades, such as 304, 316, and 410, each offering different levels of corrosion resistance, strength, and suitability for specific environments. For instance, if your project involves exposure to harsh chemicals or outdoor elements, opting for a grade like 316 is crucial because it provides superior resistance to pitting and crevice corrosion. Always check the material's composition by reviewing the certificate of analysis from the supplier, which details the alloy elements like chromium and nickel. This ensures you're getting a product that meets industry standards and won't degrade prematurely. Remember, high-quality stainless steel round bars should feel dense and uniform, without visible defects like cracks or inconsistencies in the surface finish.

Evaluating Dimensions and Specifications

Accurate dimensions are another critical factor in purchasing stainless steel round bars, as even minor discrepancies can affect the performance and fit of your project. These bars are available in a range of diameters and lengths, so always verify the exact measurements provided in the product specifications. Use calipers or measuring tools to confirm the diameter and ensure it matches your requirements, especially for precision applications like machinery components or architectural designs. Additionally, consider the tolerance levels; tighter tolerances mean more precise bars, which are ideal for high-stakes projects but may come at a higher cost. It's also wise to think about the surface finish—options like polished or brushed can impact how the bars integrate into your design, reducing friction and enhancing aesthetics. By paying close attention to these details, you can avoid installation issues and ensure seamless compatibility with your existing systems.

Assessing Corrosion Resistance and Durability

Corrosion resistance is a hallmark feature of stainless steel round bars, but not all products perform equally in challenging conditions. When making a purchase, evaluate how the bars will hold up in your specific environment, such as humid climates or chemical exposure. Look for bars that have undergone treatments like passivation, which enhances their protective oxide layer and extends their lifespan. Testing standards, such as ASTM specifications, can provide reassurance about the bar's durability; always request documentation to confirm compliance. Furthermore, consider the manufacturing process—bars produced with advanced techniques, like those from reputable sources, often exhibit better overall strength and longevity. For example, bars that are cold-drawn rather than hot-rolled may offer improved surface quality and mechanical properties. By prioritizing these aspects, you'll select stainless steel round bars that not only meet your immediate needs but also provide long-term value, reducing the need for frequent replacements.

Considering Price, Supplier Reliability, and Certifications

Price is often a deciding factor, but it's important not to sacrifice quality for cost savings when purchasing stainless steel round bars. Compare quotes from multiple suppliers while factoring in the total value, including warranties, delivery times, and after-sales support. Reliable suppliers, such as those with a proven track record in the industry, will offer transparent pricing and detailed product information, helping you avoid counterfeit or substandard goods. Always check for certifications like ISO or material safety data sheets, which indicate that the bars meet international quality standards. Additionally, inquire about the supplier's sustainability practices, as environmentally friendly production methods are increasingly important in today's market. For instance, choosing bars from companies that use recycled materials can align with green building initiatives. Finally, don't overlook logistics; ensure the supplier can deliver the bars in the required quantities and timelines to keep your project on schedule.

Final Tips for a Successful Purchase

To wrap up this guide, always conduct thorough research and perhaps even consult with experts before finalizing your purchase of stainless steel round bars. Consider your project's specific demands, such as load-bearing capacity or aesthetic requirements, and how the bars will interact with other materials. Testing samples, if possible, can provide hands-on insight into their performance. By following these steps, you'll make a well-informed decision that enhances the success of your endeavors, whether in construction, manufacturing, or creative design. Stainless steel round bars remain a versatile and reliable choice, offering a perfect balance of strength, style, and functionality for a wide array of applications.