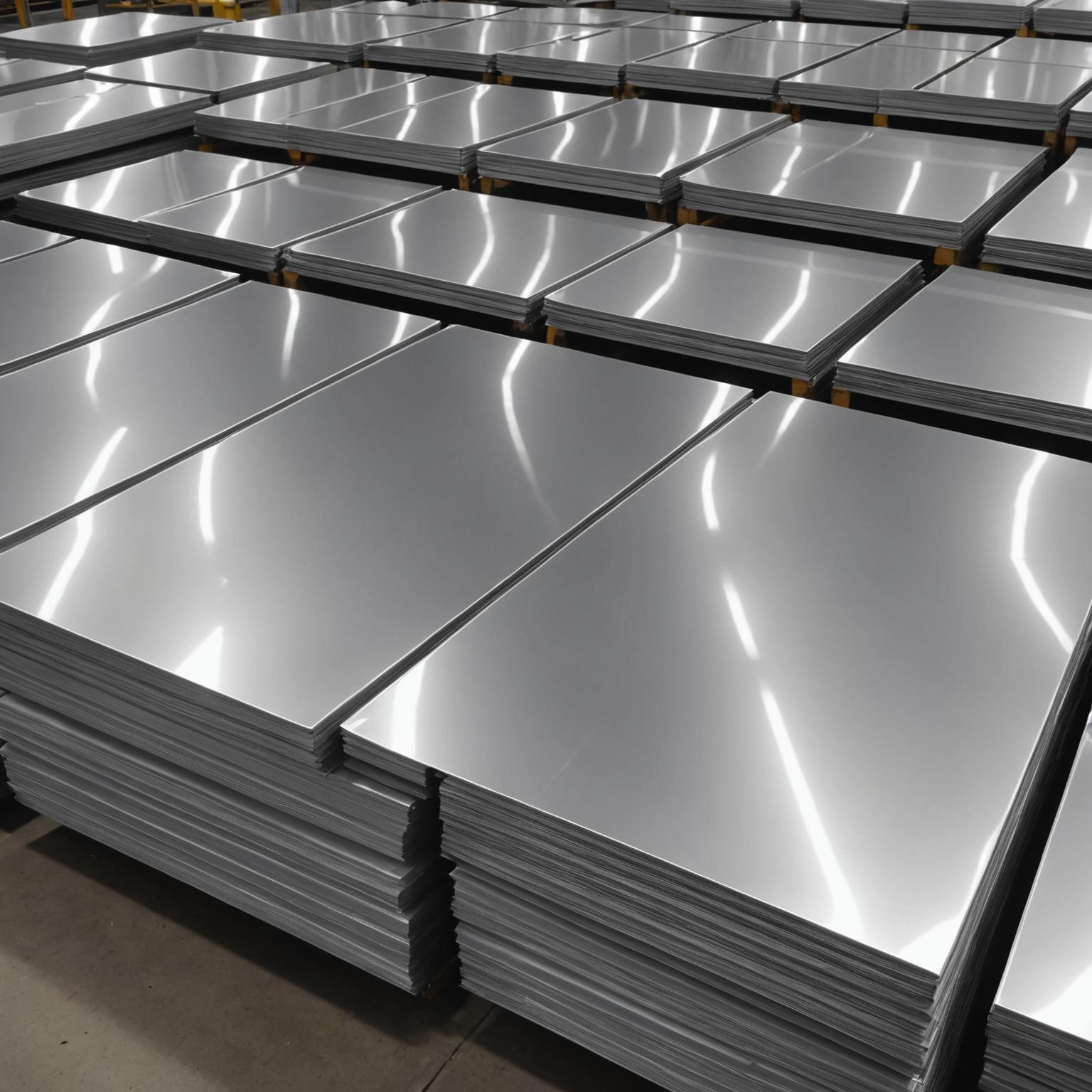

When selecting materials for architectural, industrial, or design projects, the choice often comes down to the details. For many, high-quality polished and brushed stainless steel sheets represent the pinnacle of durability and style. While both options offer the inherent strength and corrosion resistance of stainless steel, their surface finishes create distinct differences in appearance, maintenance, and longevity. Understanding these nuances is key to choosing the perfect material that not only meets but exceeds your project's requirements, ensuring a lasting and impressive result.

What Are Polished and Brushed Stainless Steel Finishes?

Before delving into a comparison of the lifespan of these finishes, it's important to understand what makes them unique. A polished stainless steel finish, often referred to as a mirror finish, is created by mechanically buffing the surface with progressively finer abrasives until it becomes highly reflective. The result is a sleek, flawless surface that exudes a modern and sophisticated aesthetic, perfect for high-end interior designs or luxurious external cladding. This mirror-like quality reflects its surroundings, adding depth and light to a space. Our premium sheets are engineered with precision to provide this impeccable surface, creating an immediate visual impact. In contrast, a brushed finish, also known as a satin finish, is produced by sanding the steel with a fine-bristle brush on a belt or wheel, which moves in a single, unidirectional pattern. This process creates fine, parallel lines in the surface, resulting in a muted, non-reflective luster that is both elegant and understated. This texture is exceptionally good at diffusing light and hiding minor imperfections.

Comparing Corrosion Resistance and Environmental Durability

At its core, all high-grade stainless steel is renowned for its exceptional corrosion resistance, a quality we engineer into every sheet we produce. This inherent durability ensures that projects maintain their pristine condition even under harsh environmental conditions. However, the surface finish can play a subtle role in performance. The smooth, non-porous surface of polished stainless steel is extremely easy to clean and offers fewer microscopic crevices where corrosive particles or moisture can settle. This can give it a slight edge in environments with high salt content, such as coastal areas, or in sanitary applications where preventing bacterial growth is critical. On the other hand, the fine grooves of a brushed finish could theoretically trap contaminants if not maintained properly. However, for the vast majority of applications, the difference in corrosion resistance is negligible, as the fundamental quality of the base material is the primary determinant of its long-term integrity. Our advanced steel sheets, embedded with anti-corrosive compounds, ensure superior performance regardless of the chosen finish.

Aesthetic Lifespan: Which Finish Hides Wear and Tear Better?

A crucial factor in the comparison of lifespan of polished and brushed stainless steel sheets is how they age visually. A material’s functional lifespan often far exceeds its aesthetic lifespan, especially in high-traffic or high-use areas. A polished, mirror-like finish is undeniably stunning, but its reflective perfection is also its greatest vulnerability. It is more prone to showing fingerprints, smudges, water spots, and fine scratches. Any blemish on its flawless surface can become immediately noticeable, requiring diligent and frequent cleaning to maintain its intended appearance. Conversely, the brushed finish is a practical champion in this regard. The unidirectional grain is incredibly effective at camouflaging minor scratches, scuffs, and everyday wear. A small scratch that might stand out on a polished surface will often blend seamlessly into the existing lines of a brushed finish, making it an ideal choice for kitchen appliances, elevator panels, countertops, and other high-contact surfaces.

Application-Specific Performance and Longevity

The ideal choice between polished and brushed stainless steel sheets often depends entirely on the specific application. For decorative architectural elements or statement pieces in a controlled environment, the brilliant aesthetic of polished steel is unmatched. It delivers a 'wow' factor that is difficult to replicate. However, for applications demanding robust performance and forgiving aesthetics, brushed steel is typically superior. In industrial settings, from high-performance vehicles to complex machinery manufacturing, the durability and low-maintenance nature of a brushed finish make it the practical choice. The versatility of our sheets, available in a range of thicknesses, allows for their use in everything from vast panel expanses to intricate fabricated components, with the finish chosen to match the environment. Ultimately, considering the daily interaction the surface will have is a key part of the selection process.

Making the Final Decision: Durability Meets Design

In summary, when comparing the lifespan of these two popular finishes, the answer is not about which is universally better, but which is better for your specific needs. Polished stainless steel offers a superior, high-impact aesthetic but demands more care to keep it looking pristine. Brushed stainless steel provides a more forgiving and practical surface that gracefully hides the rigors of daily use. Regardless of your choice, the most critical factor is the quality of the underlying material. Our premium polished and brushed stainless steel sheets are meticulously fabricated and subjected to stringent quality controls, ensuring a foundation of unparalleled strength and corrosion resistance. This commitment to quality means that whether you prioritize flawless reflection or practical elegance, your project is built on a material designed to last, where strength converges with style.