Choosing the right building materials is a foundational step for any construction or design project, directly impacting both the aesthetic appeal and the long-term durability of the structure. Among a sea of options, the architectural stainless steel sheet stands out as a premier choice for its blend of sophistication, strength, and versatility. However, with various grades, finishes, and thicknesses available, knowing how to choose the correct sheet for your specific needs is paramount to achieving a successful outcome. This guide will walk you through the essential factors to consider, ensuring you select a product that not only looks incredible but also performs flawlessly for years to come.

Understanding the Different Grades of Stainless Steel

Before you can decide on a finish or thickness, you must understand the material's core composition. The 'grade' of stainless steel refers to its quality, durability, and resistance to corrosion. For architectural purposes, two grades are most commonly used: Grade 304 and Grade 316. Grade 304 is the industry workhorse; it offers excellent corrosion resistance in most environments and is more cost-effective. It's an ideal choice for indoor applications like decorative panels, kitchen backsplashes, and interior trim, as well as for outdoor use in non-coastal, low-pollution areas. On the other hand, Grade 316, often called 'marine grade,' contains molybdenum. This addition gives it superior resistance to chlorides, such as salt from seawater spray and de-icing chemicals. If your project is located in a coastal region, a heavy industrial zone, or an area where de-icing salts are frequently used, investing in Grade 316 is a non-negotiable step to prevent rust and degradation over time.

How to Choose the Perfect Finish for Your Project

The finish of an architectural stainless steel sheet dictates its visual character and can also influence its practicality. A brushed finish is one of the most popular choices for modern design. Its fine, parallel lines create a subtle texture that diffuses light, minimizes the appearance of fingerprints, and effectively hides minor scratches, making it perfect for high-traffic areas like elevator interiors, wall panels, and appliance covers. For a bolder, more luxurious statement, a polished or mirror finish offers high reflectivity that can make spaces feel larger and more open. This is often used for accent pieces, column wraps, and ceiling tiles in high-end residential or commercial spaces, though it requires more diligent cleaning to maintain its pristine look. Other options include a satin finish, which provides a softer, lower-reflectivity lustre, or patterned and embossed finishes. These textured surfaces add a unique decorative element while significantly increasing the material's rigidity and ability to hide dents and dings, making them suitable for high-impact applications.

Considering Thickness (Gauge) and Form Factor

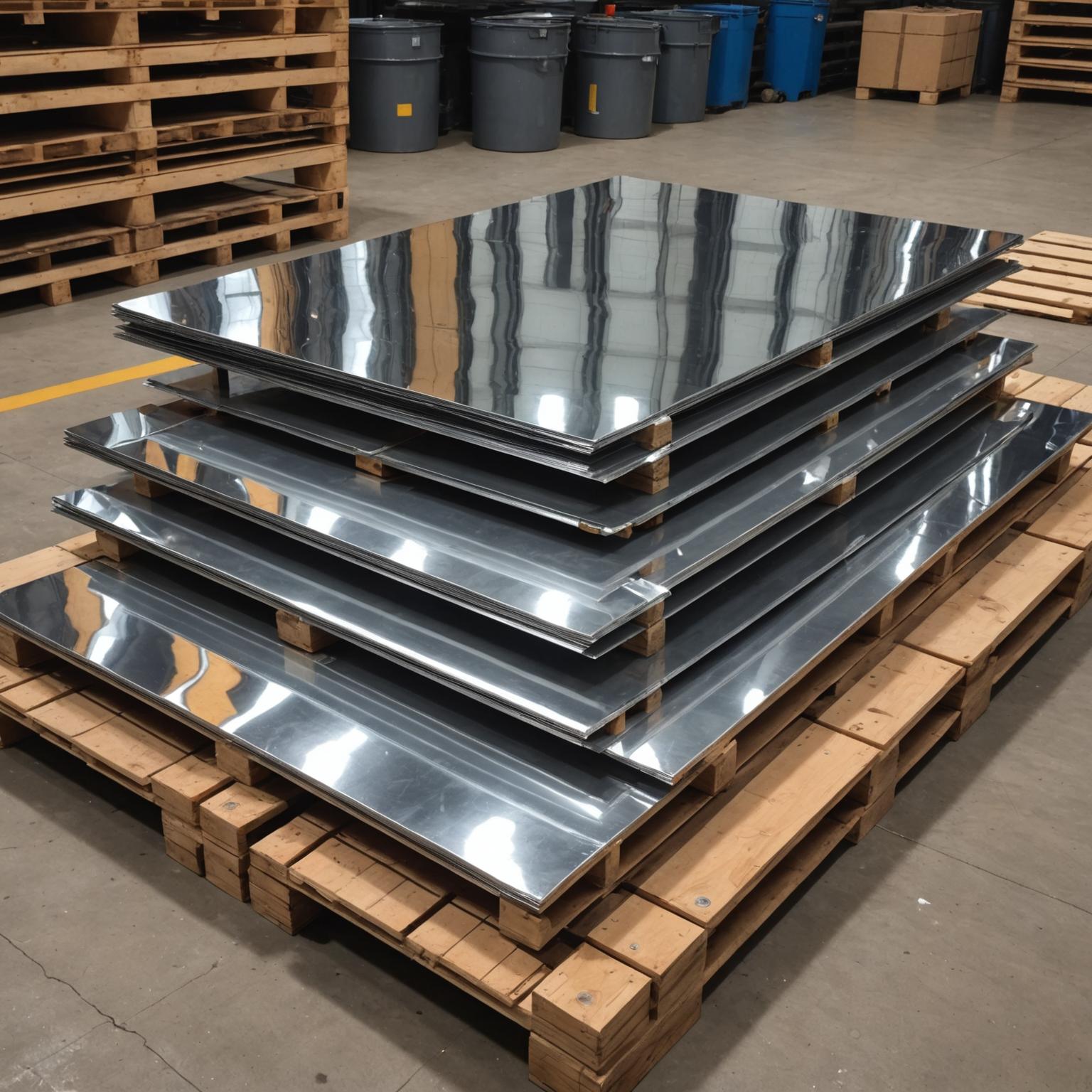

The thickness of the stainless steel, referred to as its gauge, is a critical factor for both structural integrity and application suitability. In the gauge system, a lower number indicates a thicker sheet, while a higher number signifies a thinner one. For applications requiring structural support or high dent resistance, such as exterior cladding, roofing, or robust wall protection systems, a thicker gauge (e.g., 16 or 18 gauge) is necessary. These thicker sheets provide the rigidity needed to withstand physical impact and environmental stress. Conversely, for primarily decorative interior applications where the sheet is being applied over a solid substrate—like a column wrap, display panel, or backsplash—a thinner gauge (e.g., 22 or 24 gauge) is often sufficient. Thinner sheets are lighter, more flexible, and generally more economical, making them easier to fabricate and install for aesthetic purposes.

Matching the Steel to the Environment

A crucial part of the selection process is holistically evaluating the environment where the material will be installed. This goes beyond the simple indoor-versus-outdoor distinction. Consider the micro-environment. Will the stainless steel be exposed to direct sunlight for most of the day? A highly reflective polished finish might create unwanted glare. Is it in a busy hallway? A brushed or patterned finish will be more forgiving of daily wear and tear. Is the application in a commercial kitchen or a laboratory where it will be exposed to various chemicals? Grade 316 might be a safer choice even if the location is not coastal. By asking how to choose the material based on these specific, real-world conditions, you ensure that the architectural stainless steel sheet will not only meet but exceed performance expectations, maintaining its integrity and beauty throughout its service life.

Making Your Final Decision

Selecting the ideal architectural stainless steel sheet is a balancing act between aesthetics, performance, environment, and budget. Start by defining the application's environment to determine the necessary grade—Grade 304 for most standard locations and Grade 316 for harsh or coastal settings. Next, consider the desired visual effect and the level of public interaction to choose the most appropriate finish, from practical brushed to elegant mirror polish. Finally, assess the structural requirements to select the correct gauge. By carefully considering these key elements, you can confidently choose a product that provides the perfect fusion of form and function, delivering an enduring and sophisticated solution for your architectural vision.