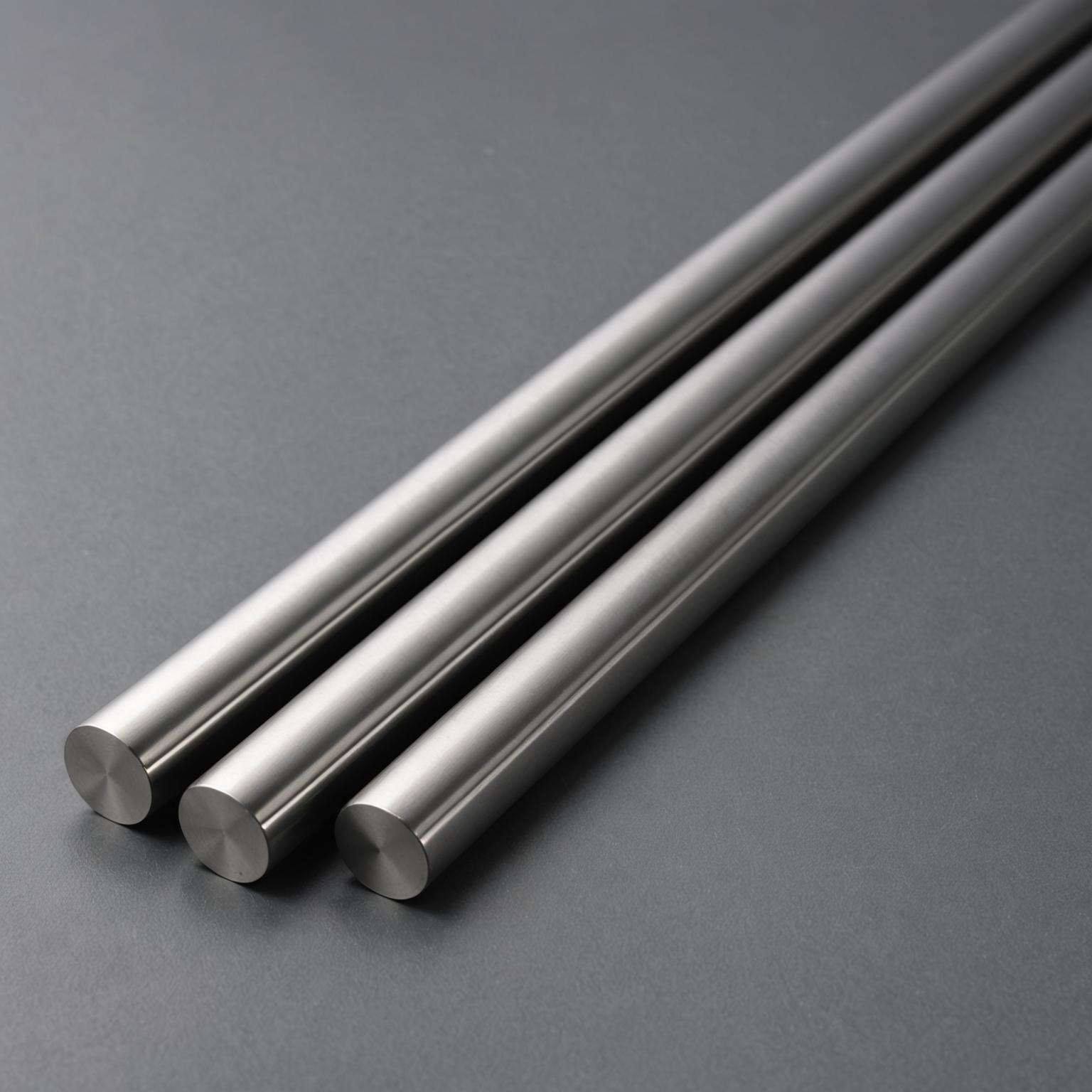

In the vast world of industrial and construction materials, few components offer the same blend of strength, durability, and aesthetic appeal as the 10mm stainless steel round bar. This seemingly simple component is a cornerstone of modern engineering, architecture, and manufacturing, providing a reliable foundation for countless applications. For professionals seeking high-quality materials, sourcing from a reputable supplier like Span International ensures that every project starts with the best possible foundation. This guide will walk you through everything you need to know about these versatile bars, from their fundamental properties to practical tips on selection and application.

What Exactly is a 10mm Stainless Steel Round Bar?

At its core, the name itself describes the product perfectly. '10mm' refers to the diameter of the bar, a specific and common size that is ideal for applications requiring moderate strength without excessive bulk. 'Round bar' indicates its solid, cylindrical shape, which provides uniform strength in all directions. The most critical part, however, is 'stainless steel.' This is not a single material but a family of iron-based alloys containing a minimum of approximately 10.5% chromium. It is this chromium content that gives stainless steel its famous 'stainless' quality. When exposed to oxygen, the chromium forms a thin, invisible, and passive layer of chromium oxide on the surface. This layer is self-healing; if it's scratched or damaged, it instantly reforms, protecting the underlying steel from rust and corrosion. Beyond chromium, other elements like nickel and molybdenum are often added to enhance specific properties, such as formability, strength, and resistance to specific types of corrosion.

There are several grades of stainless steel, but for round bars, you will most commonly encounter Grade 304 and Grade 316. Grade 304 is the most widely used stainless steel, offering an excellent combination of corrosion resistance, weldability, and strength, making it a versatile workhorse for general applications. Grade 316 contains molybdenum, which significantly enhances its resistance to corrosion, particularly from chlorides and other industrial solvents. This makes it the premier choice for marine environments, coastal applications, and the food processing and chemical industries.

Where Are 10mm Stainless Steel Round Bars Used?

The versatility of the 10mm stainless steel round bar means its applications are incredibly diverse, spanning numerous industries. In construction and architecture, these bars are frequently used for creating sturdy yet elegant railings, balustrades, and support structures. Their clean, modern aesthetic makes them a favorite for both interior and exterior design elements. They are also used as reinforcing bars (rebars) in concrete where corrosion is a major concern, such as in bridges and coastal buildings.

Within the manufacturing sector, these bars are fundamental. They are machined into a vast array of components, including shafts, axles, gears, fasteners, and bolts. Their dimensional accuracy and smooth surface finish are critical for creating precision parts that machinery relies on. The automotive industry utilizes stainless steel bars for durable components in exhaust systems, grilles, and trim, where they must withstand high temperatures and exposure to road salts. Furthermore, in the food and beverage industry, hygiene is paramount. Stainless steel is non-porous and easy to clean, preventing bacterial growth. A 10mm stainless steel round bar is often fabricated into equipment parts, conveyor components, and support framework for processing lines, ensuring compliance with strict health and safety standards.

A Guide to Selecting the Perfect Stainless Steel Bar

Choosing the correct bar for your project is crucial for ensuring longevity, safety, and performance. The first and most important decision is selecting the right grade. For most indoor or general outdoor applications, Grade 304 is an excellent and cost-effective choice. It resists atmospheric corrosion, common chemicals, and food products well. However, if your project will be exposed to saltwater, de-icing salts, or harsh chemical environments, investing in Grade 316 is essential. The added molybdenum provides superior protection against pitting and crevice corrosion, which can compromise the structural integrity of the material over time.

Once you've chosen the grade, you need to consider quality and specifications. Always source your materials from a trusted supplier like Span International, who can provide material test reports and certificates of conformity. These documents verify the chemical composition and mechanical properties of the steel, ensuring it meets recognized standards like ASTM or ISO. Inspect the bar for dimensional tolerance – is it consistently 10mm in diameter along its length? Also, consider the surface finish. A standard mill finish is fine for industrial parts, but for architectural or decorative uses, you might prefer a brushed or polished finish for a more refined look. A reputable supplier will offer various finishing options to meet your aesthetic requirements.

Tips for Cutting, Welding, and Finishing

Working with stainless steel requires slightly different techniques than working with mild steel due to its properties. When cutting a 10mm stainless steel round bar, it's important to use tools designed for the task to avoid work hardening, a phenomenon where the steel becomes harder and more difficult to cut as you work it. Abrasive cut-off wheels or a band saw with a bi-metal blade at a slow speed and with proper lubrication are recommended. Applying steady pressure is key to preventing the blade from simply rubbing against the surface and generating excessive heat.

Welding stainless steel also requires specific knowledge. TIG (Tungsten Inert Gas) welding is often preferred for stainless steel as it produces a clean, high-quality weld with excellent control. MIG (Metal Inert Gas) welding is faster and also effective. It is crucial to use a filler rod or wire that matches the grade of the base metal (e.g., 308L for 304 stainless, 316L for 316 stainless) to maintain the corrosion-resistant properties of the weld zone. After welding, the area must be thoroughly cleaned to remove any heat tint or weld scale. This process, often involving wire brushing (with a stainless steel brush, never a carbon steel one) and passivation with an acid solution, restores the passive chromium oxide layer and ensures the weld is as corrosion-resistant as the rest of the bar.

How to Maintain Your Stainless Steel Components

One of the biggest advantages of stainless steel is its low maintenance requirement, but 'low maintenance' does not mean 'no maintenance.' To keep your stainless steel components looking their best and performing optimally, regular cleaning is recommended. For most applications, a simple cleaning with soap or a mild detergent and warm water, followed by a rinse with clean water and drying with a soft cloth, is sufficient to remove dirt and grime. This is particularly important for exterior applications where deposits can accumulate and potentially lead to localized corrosion over time.

For more stubborn stains or minor discoloration, a non-abrasive cleaner can be used. Always rub in the direction of the polish lines to avoid scratching the surface. It's vital to avoid using harsh abrasives like steel wool or cleaners containing chlorides (bleach), as these can damage the passive layer and induce rusting. If small rust spots do appear, often due to contamination from carbon steel particles, they can usually be removed with a specialized stainless steel cleaner. By following these simple maintenance steps, you can ensure that your stainless steel installations and components retain their beauty and integrity for decades.

The Enduring Value of Stainless Steel

In conclusion, the 10mm stainless steel round bar is far more than just a piece of metal; it is a highly engineered material solution that offers an unmatched combination of strength, longevity, corrosion resistance, and aesthetic grace. Its adaptability makes it an indispensable component across a vast spectrum of projects, from critical industrial machinery to elegant architectural designs. By understanding the different grades, selecting a quality product from a reliable source like Span International, and using the proper techniques for fabrication and maintenance, you can harness the full potential of this remarkable material. Investing in stainless steel is an investment in quality and durability that pays dividends for years to come.