Understanding Surface Consistency

Maintaining surface consistency is crucial for both aesthetic and structural integrity in various projects, especially after welding special-shaped pipes. The importance of achieving a seamless, consistent surface spans across multiple fields, from architectural applications to furniture design. It ensures that welded structures remain durable, visually appealing, and fit for purpose. Surface consistency speaks to the quality and precision of craftsmanship and is a vital component in the overall success of any constructed piece.

Steps to Maintain Surface Consistency After Welding Special-Shaped Pipe

After welding special-shaped pipes, specific techniques can help achieve and maintain surface consistency. First, ensuring the welding equipment is properly calibrated can make a significant difference in the outcome. Equipment that is in optimal condition aids in precise welding, minimizing irregularities.

Once the welding is complete, inspection becomes vital. Assessing the welded areas with a keen eye allows you to identify any inconsistencies or faults. Tools like micrometers or laser measurement devices provide accurate readings and ensure that every welded joint meets the required specifications.

Next, utilizing finishing techniques can greatly enhance surface consistency. Sanding or grinding, followed by polishing, helps to smooth out any uneven sections. For stainless steel surfaces, using abrasive pads or polishing compounds specifically designed for stainless steel yields excellent results. This step not only improves the appearance but also enhances the surface’s ability to resist corrosion.

Proactive Measures for Long-Lasting Consistency

Long-term consistency requires proactive maintenance steps. Regular cleaning of the welded surfaces prevents residue buildup, which could compromise the finish over time. Moreover, applying protective coatings can extend the lifespan of the surface consistency by shielding the metal from environmental factors such as moisture or chemical exposure.

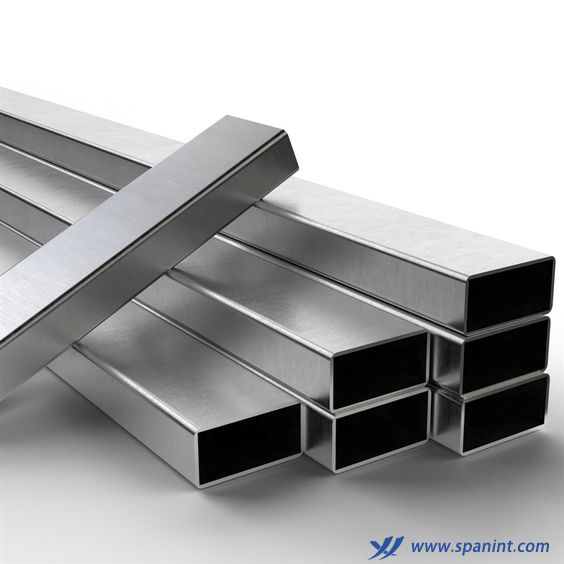

Understanding the alloy compositions of the materials being used is also crucial. Choosing high-grade stainless steel, for instance, promises better durability and resistance, aligning with the superior engineering principles behind the company’s latest stainless steel square tubing. Employing stainless steel not only showcases the aesthetic simplicity but also the minimalist elegance that can be achieved, adding value and functionality to diversified applications.

Additionally, collaboration with skilled professionals can ensure that the techniques employed for maintaining surface consistency are applied effectively. Their expertise contributes to thorough inspections and the implementation of best practices in welding and finishing.

Conclusion

In conclusion, maintaining surface consistency, especially after welding special-shaped pipes, is an art and a science that necessitates precision, proper equipment, and appropriate materials. The sleek and modern stainless steel square tubing referenced is a testament to these principles, offering a foundation of robust functionality paired with sophisticated aesthetics. By adhering to meticulous standards and leveraging expert skills, the challenge of preserving surface consistency can become an opportunity to elevate any project into an architectural masterpiece.