Stainless steel sheet: characteristics, applications and purchase guide

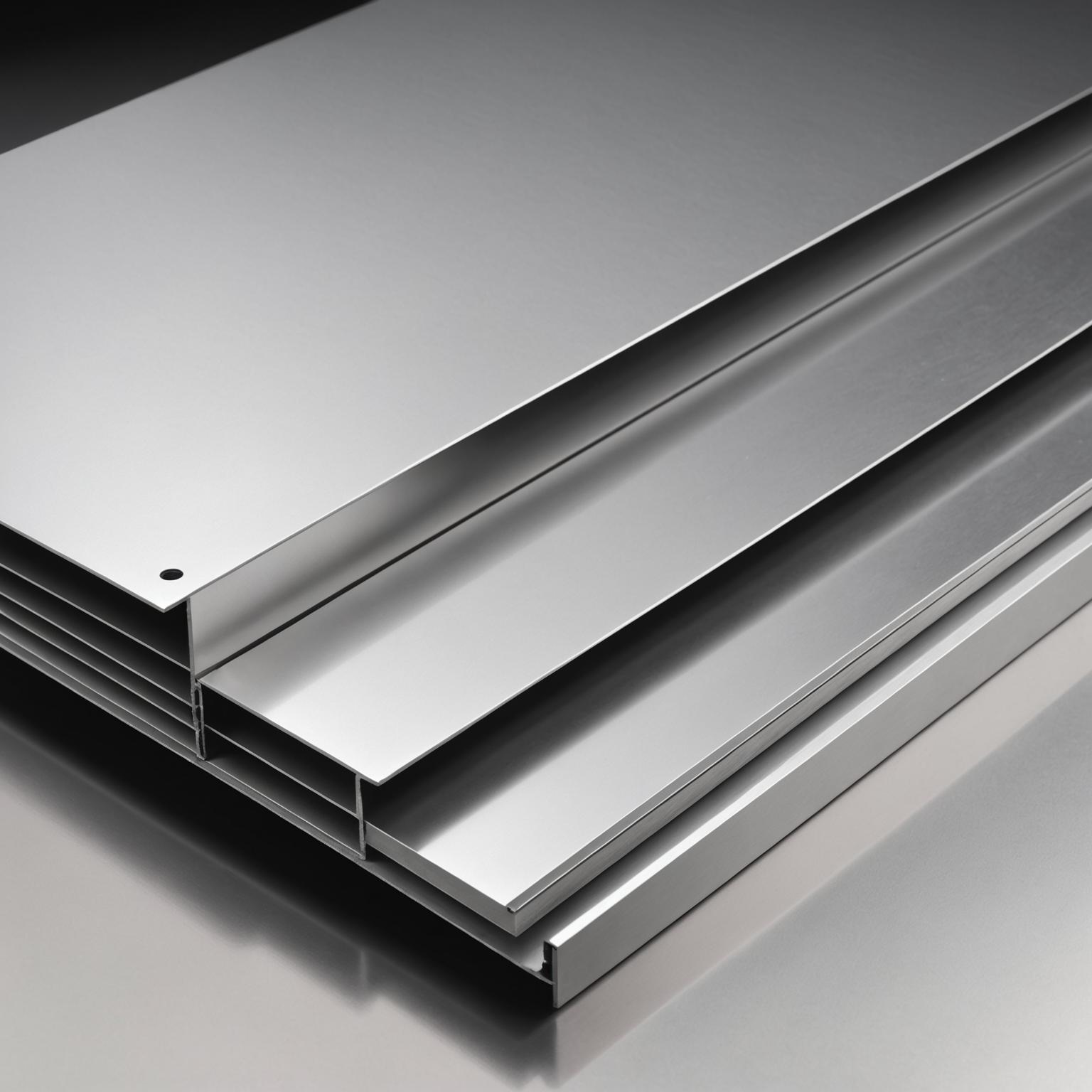

Introduction to stainless steel sheet

Stainless steel sheet is a corrosion-resistant, high-temperature resistant and high-strength metal material, widely used in construction, manufacturing, food processing, medical equipment and other fields. Its main components are alloy elements such as iron, chromium, and nickel, and it has excellent anti-oxidation and corrosion resistance.

Classification of stainless steel sheet

Classification by material

Austenitic stainless steel (304, 316): Strong corrosion resistance, suitable for food and chemical industries.

Martensitic stainless steel (410, 420): High hardness, often used for knives and mechanical parts.

Ferritic stainless steel (430): Low cost, suitable for home appliances and decorative materials.

Classification by surface treatment

Mirror stainless steel: High gloss, used for decoration and high-end equipment.

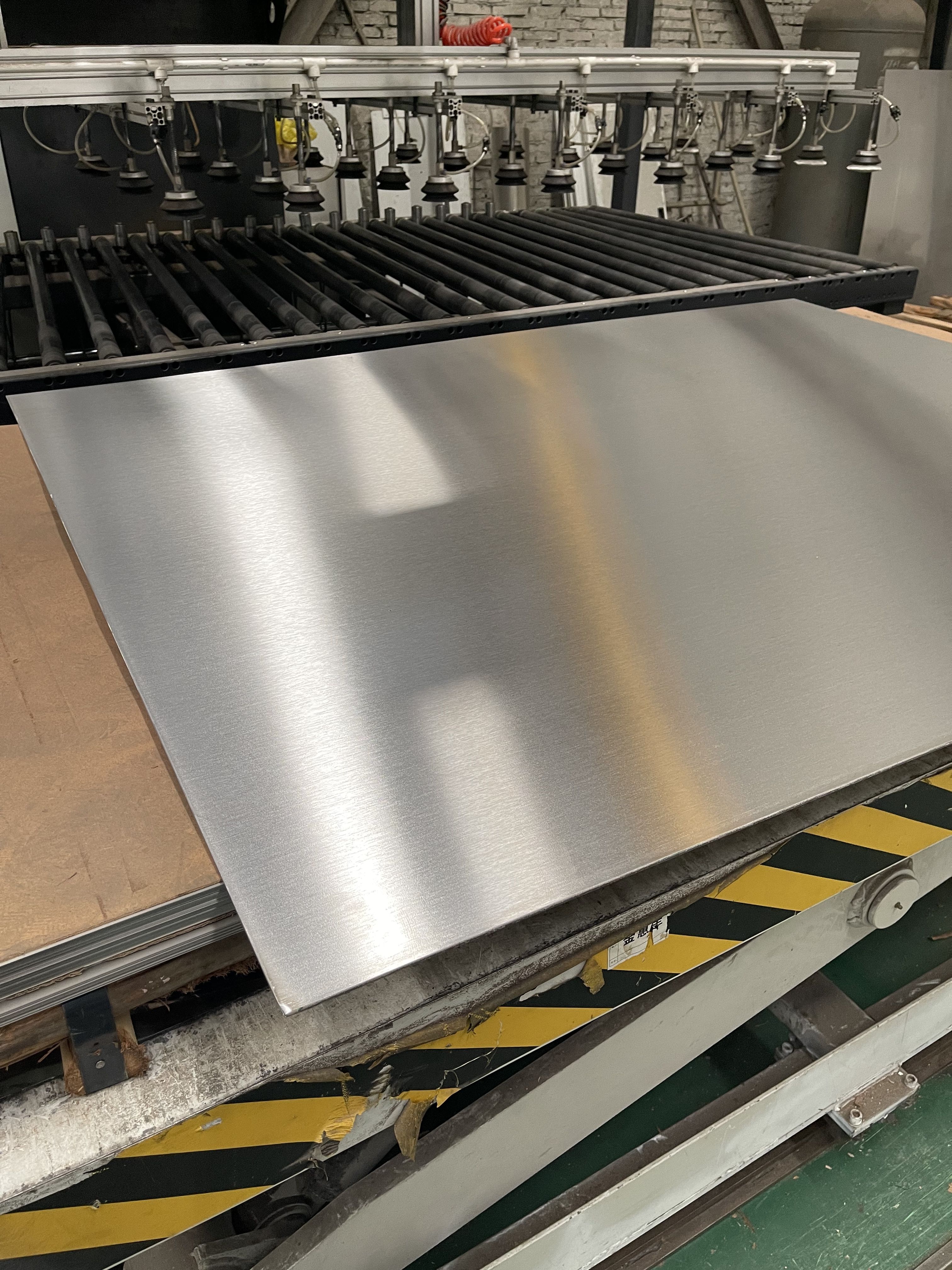

Brushed stainless steel: Scratch-resistant and wear-resistant, suitable for home appliances and elevator panels.

Sandblasted stainless steel: Matt texture, suitable for building exterior walls and interior decoration.

Classification by thickness

Thin sheet (0.2mm-3mm)

Medium sheet (3mm-20mm)

Thick sheet (20mm and above)

Application areas of stainless steel sheet

Construction industry: curtain wall, elevator decoration, door and window frame

Food processing: kitchen equipment, storage tank, conveyor belt

Medical industry: surgical instruments, medical equipment

Industrial manufacturing: chemical equipment, auto parts

Home decoration: cabinets, countertops, lamps

How to choose stainless steel sheet?

Determine the use: Different environments (such as humidity, high temperature) need to choose suitable materials (such as 316 seawater corrosion resistance).

Check the surface quality: no scratches, no oxidation spots, to ensure that the process meets the standards.

Certification standards: Check whether it meets international/national standards such as ASTM, JIS, GB, etc.

Supplier reputation: Choose a regular manufacturer to ensure the authenticity of the material and after-sales service.

Maintenance and care of stainless steel sheet

Clean regularly to avoid long-term contact with chloride ions (such as salt water).

Use neutral detergent to avoid strong acid and alkali corrosion on the surface.

Brushed or mirrored stainless steel can be kept shiny with special care agents.

Conclusion

Stainless steel sheets have become an important material for modern industry and construction due to their durability and beauty. Proper selection and maintenance can extend their service life and ensure optimal performance. For further consultation, please contact a professional stainless steel supplier.