Navigation Stainless Steel Finish: 2B and 8K Depth Appearance

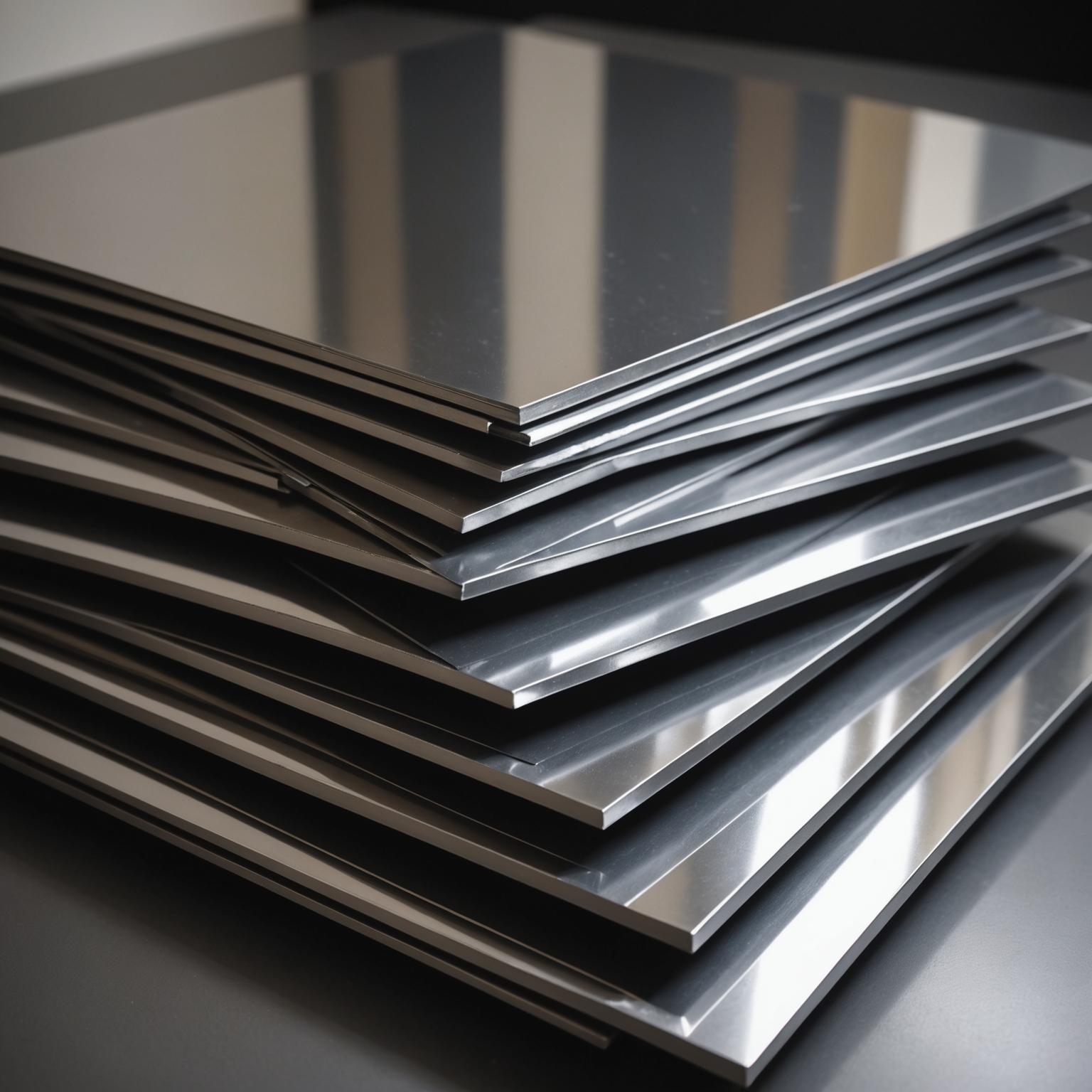

When choosing materials for industrial, architectural or decorative projects, stainless steel plates are often the highest competitors due to their durability, corrosion resistance and aesthetic versatility. However, the term “stainless steel” covers a wide variety of achievements and is crucial to accomplish. At the most discussed, sometimes confusing are the 2B and 8K finishes. Understanding the nuances between these two surface treatments is essential to make informed decisions that align with functional requirements and required visual outcomes. This exploration will delve into the characteristics of 2B and 8K finishes, highlighting their production, appearance, application and what really makes them unique.

Understanding standard: Characteristics of 2B-faced stainless steel plates

2B finishes are perhaps the most common and widely used mill finishes for cold rolling stainless steel plates. The name "2b" denotes a bright, cold-rolled surface achieved by a specific sequence of operations. After cold rolling, the stainless steel is annealed (heat-treated to soften and relieve stress) and then marinated (chemically dropping to remove impurities). The final step involves a light "Skin Pass" or "Pinch Pass" on the polished roll. The final pass gives a smooth, moderately reflective surface that is brighter than a 2D (dappy) surface, but not as shiny as a highly polished option. The value of the corrosion resistance of 2B finishes (its inherent steel grade, relatively low cost and smooth surface) is worth it and it provides a good foundation for further polishing or finishing if needed. It is often found in applications such as food processing equipment, chemical tanks, pipe fixtures and general sheet metal work, where features, clean and fairly bright surfaces are required without the need to spend more polishes.

The Peak of Poland: Exploring 8k Mirror-Faced Stainless Steel Watch

In sharp contrast to the more practical 2B, the 8K finish represents the polished apex of the stainless steel plate, commonly known as a "mirror finish" or "super mirror." Achieving an 8K surface is a meticulous and labor-intensive process. It usually starts with paper with a good initial surface (usually 2B or BA (bright annealed) finish and then mechanically polished with a series of gradually fine abrasives. The process ends with the climax of extremely high polishing compounds. The purpose is to eliminate all grit lines and surface defects, resulting in a highly reflective non-directional surface with excellent image clarity, like a glass mirror. Due to its original, delicate nature, 8K finished stainless steel plates are often equipped with protective films to prevent scratches during processing and manufacturing. Its main applications are aesthetics, including architectural decorative elements, columnar covers, reflective surfaces, high-end elevators, decorative decorations, and anything that requires an amazing, flawless appearance.

Appearance and reflectivity: The story of two surfaces

The most direct and striking difference between the 2B and 8K finishes is their visual characteristics, especially their reflectivity. The 2B-faced stainless steel plate presents a smooth surface with a moderate diffuse reflectivity. Although bright, it does not provide clear, clear reflections. Instead, the light spreads some subtle sheen. This makes it undesirable for environmental practicality for high glare. Instead, the 8K finish is to maximize reflectivity. It has a non-directional, mirrored surface that provides clear, clear image reflections similar to looking at a glass mirror. Visual influence is one of luxury, depth and brilliance. This high reflectivity can be used strategically in the design to make the space appear larger or produce a dramatic visual effect. While the 2B provides clean, full-featured brightness, the 8K offers an almost flawless highlight aesthetic statement.

Clarification: What are the differences in production, cost and practicality?

Aside from aesthetics, it is crucial to understand the differences in manufacturing processes, the cost of the result, and what the everyday practicality of 2B and 8K finishes are. 2B finishes are standard mill operation and are integrated into the main production of cold rolling stainless steel plates. This makes it a relatively cost-effective option. However, 8K finishes involve a lot of mill post-treatment. The multiple stages of grinding, polishing and polishing require specialized equipment and considerable labor, making 8K stainless steel plates much more expensive than 2B. In terms of practicality, the 2B surface is more tolerant. Although they can scratch, smaller defects are less noticeable on highly polished surfaces. Fingerprints and stains are not too obvious. Due to its perfection, an 8k mirrored surface performs excellently, which is very easy to display fingerprints, stains and scratches, requiring careful treatment during the manufacturing process and regular, meticulous cleaning to maintain its original appearance. The choice between 2B and 8K is often determined by balancing the need for visual impact with the need for budget and maintenance considerations.

Applicability: 2B and 8K finish shining

The unique characteristics of 2B and 8K finishes determine their applicability to different applications. In many industries, it has good corrosion resistance, smooth surface and cost-effectiveness, good corrosion resistance, smooth surface and cost-effectiveness. It is ideal for electrical appliances, industrial equipment, food and beverage processing machinery, chemical plant components and high upgrade finishes that are not the main requirements for general manufacturing equipment, industrial equipment, food and beverage processing machinery, chemical plant components and general manufacturing. Its versatility also makes it a common starting point for other finishes. On the other hand, the 8K finish is almost chosen for its decorative appeal. It found its place in famous architectural projects, luxury retail interiors, high-end elevators, decorative panels, signage and art installations. For 8k stainless steel plates, ideally the environment should be an environment that can be appreciated and maintained, unless specifically protected or designed, usually in less important or under-traffic areas.

Make an informed decision: Choose 2B and 8K for your project

Choosing the appropriate finish for your stainless steel plate needs to carefully evaluate project priorities. If the budget is the primary limitation and the application is more decorative than the decoration, or the parts will be hidden or further processed, a 2B finish is usually a smarter and more economical option. Its inherent corrosion resistance and smoothness are sufficient for a wide range of uses. However, if the project requires maximum visual impact, a luxurious look and high reflectivity are key design elements, then as long as the budget can accommodate its higher costs and the end-use environment allows it to maintain. Considerations should also include the manufacturing process involved; the original surface of the 8K finish requires more careful treatment to avoid damage, which can increase the complexity and cost of manufacturing compared to 2B stainless steel plates.

Conclusion: Hug with 2B and 8K functions simple or reflective grand

In the field of stainless steel surface treatment, 2B and 8K finishes represent two distinct ends of aesthetics and processing spectrum. 2B finishes provide a practical, cost-effective solution with a clean, medium bright look that suits a wide range of industrial and functional applications. In contrast, the 8K finish offers a stunning highly reflective mirror, chosen for its dramatic visual appeal in decorative and built environments that are crucial to luxury and splendor. Both are inherently superior. Instead, their value depends on the specific requirements of the application. By understanding the basic characteristics of 2B and 8K finishes, production methods, and practical implications, designers, engineers and manufacturers can confidently choose the stainless steel table that best suits their project goals, whether they need low-key features or striking glory.