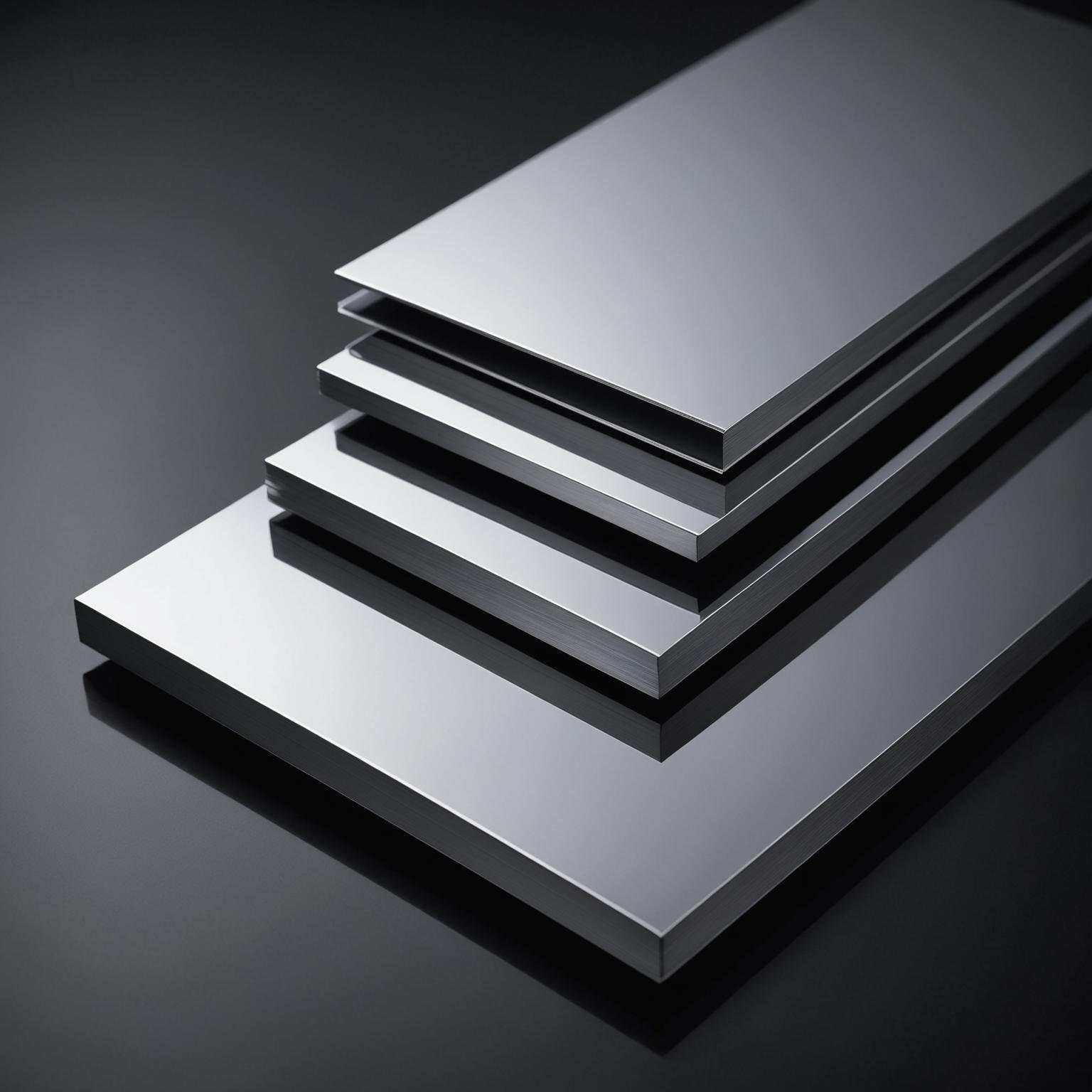

Learn about stainless steel finishes: Explore 2B and 8K

When it comes to choosing materials for industrial, architectural or decorative applications, the durability, corrosion resistance and aesthetic versatility of stainless steel are striking. However, not all stainless steel surfaces are equal. The surface of stainless steel plates plays a crucial role in their appearance, performance and suitability for a particular environment. Of the countless finishes available, two common but different options are the 2B and 8K finishes. Understanding what the differences are between these finishes is crucial for manufacturers, designers and engineers to make informed decisions. This article will delve into the characteristics, production methods and applications of 2B and 8K stainless steel surface finishes and provide a clear comparison to guide your selection process.

Decode 2B finishes on stainless steel plate

2B finish is one of the most widely used and recognized finishes for stainless steel products. The name "2b" means a bright cold coating. Its production involves a series of steps: the stainless steel is first cold-rolled to the desired thickness, then annealed (heat treatment) to restore its ductility and relieve internal stress, and then marinated in an acid solution to remove any proportions or impurities formed during the annealing process. The final key step is to have a mild "skin pass" or "Pinch Pass" between the polished rolls. The last pass will give a smooth, medium reflective surface that is more uniform and brighter than the 2D (dwilight, cold) finish. The result of the 2B finish is a matte, grey and slightly shiny finish. It doesn't look like a mirror, but provides a clean and functional aesthetic. Key features include good profile, good corrosion (inherent in stainless steel grade), and surfaces that are usually easy to clean. Additionally, 2B finishes are an excellent basis for subsequent polishing, painting or paint processes. Commonly used are widespread, and high reflectivity is not the main problem found in industrial equipment, chemical processing plants, food and beverage machinery, kitchen utensils, automotive components, and various utilitarian architectural elements. Its cost-effectiveness and practicality make it a major force in many industries.

Revealed the glory: 8K mirror finish

In sharp contrast to the practicality of the 2B finish, the 8K finish (also known as the No. 8 or mirror finish) represents the pinnacle of polished stainless steel surfaces. This finish is characterized by its highly reflective, non-directional, mirror-like appearance. Achieve 8K finishes on stainless steel plates is a labor-intensive process that usually starts with high-quality base surfaces, usually a 2B or even bright annealed (BA) finish. The basic material uses gradually fine abrasives for a series of meticulous mechanical polishing operations. This gradual abrasion eliminates surface defects and creates a smoother surface. The final stage involves the use of extremely fine polishing compounds and soft mops to achieve a flawless, highly glossy and defect-free surface that reflects the image with minimal distortion, just like a glass mirror. The main feature of the 8K finish is its excellent aesthetic appeal. It offers unparalleled reflectivity and a sense of luxury and modernity. Although visually stunning, 8K surfaces are easier to show fingerprints, stains and scratches than blunt finishes. It is also more expensive due to extensive processing. The application of 8K stainless steel plates is mainly decorative, including building exterior walls, elevator interiors, hall accents, high-end retail displays, signage, decorative decor, kitchen backsplash to provide a high-quality exterior and require a stunning visual impact.

2B vs 8K: Direct comparison of stainless steel surface finish

When specifying stainless steel tables for any project, it is crucial to understand the basic differences between 2B and 8K finishes. The most direct difference is their appearance and reflectivity. The 2B finish provides a smooth, moderately reflective, slightly matte finish that provides a functional and a clean look. In contrast, the 8K finish has an unusually shiny finish with a mirror-like polish that provides high definition and reflectivity designed to maximize visual impact. This significant visual difference stems from their production process. 2B finishes are standard mill finishes achieved through cold rolling, annealing, pickling and light skin passes. However, the 8K finish requires a lot of additional mechanical polishing and polishing, and gradually grinding the abrasive beyond the initial mill. Therefore, the meaning of cost varies greatly. 2B is one of the most economical stainless steel finishes, and 8K is much more expensive due to the labor, time and specialized materials involved in production. In terms of durability and maintenance, the 2B surface is relatively forgiving, better concealing minor scratches and wear, and is often easier to maintain in demanding environments. While smooth and easy to wipe clean, the 8K surface is easy to show fingerprints, stains, and more easily see visible scratches, so it requires more careful handling and frequent cleaning to maintain its original appearance. Both finishes retain the inherent corrosion of stainless steel alloys, and although in very specific cases, the very high smoothness of 8K finishes may theoretically bring a slight advantage, this is not the main determinant. For manufacturing, 2B stainless steel tables are an excellent substrate for further processing (such as painting or additional polishing), while welded 8K boards require special care to protect the finish, and any damage can be difficult to repair to its original mirrored state.

Navigation Selection: When to select 2B or 8K

Determining between 2B and 8K finishes on stainless steel plates depends heavily on the specific requirements and priorities of your application. The main consideration is usually the intended purpose: Are stainless steel components primarily functional, or are they mainly used for aesthetic enhancement? If the application is industrial, internal or basic, clean metal looks sufficient without requiring high reflectivity places, 2B finishes are usually a more practical and economical option. Its durability and low cost make it ideal for machinery, tanks, unexposed building elements and general manufacturing. Conversely, if the project needs to have a high-end, visually striking look, such as in luxury architectural designs, decorative features, or premium consumer products, the 8K mirror finish is unparalleled. Budget is another key factor; the significant cost difference between 2B and 8K means that the latter is generally reserved for applications where their aesthetic contributions justify higher investments. Maintenance and environmental exposure also play a role. A more robust, less 2B finish is desirable in areas with high flow rates or in environments where surfaces may be prone to wear or stain. 8K finishes thrives in protected or exhibiting a meticulous and clean environment. If stainless steel plates serve as the basis for further surface treatments such as painting or professional textures, then starting with a cost-effective 2B finish makes more sense than investing in an 8K finish. An effective understanding of the differences in these aspects will lead to more appropriate material choices.

Summary of thought: Unique roles for 2B and 8K finishes

In short, 2B and 8K are important in the field of stainless steel products, and the finishes are used in the field of stainless steel products, each product has different purposes and meets different application needs. 2B finishes are a multifunctional workhorse in the industry – a cost-effective, functional and reasonably smooth surface that provides a solid foundation for a variety of uses from industrial equipment to everyday equipment. Its practicality and adaptability make it an ubiquitous choice. On the other hand, the 8K finish embodies aesthetic perfection, providing a bright mirror polish that converts stainless steel into luxury and high visual impact materials. It is the preferred option for decorative applications where complex and reflective surfaces are crucial. The journey from raw materials to the last 2b and 8k surfaces involves completely different treatments, which directly translate into their respective costs and applicability to different environments. Choosing these two correctly requires careful evaluation of aesthetic goals, performance requirements, maintenance considerations, and critical budget constraints. By admiring the unique properties and contrasting properties of 2B and 8K finishes, designers and engineers can ensure that the selected stainless steel table not only meets but also enhances the overall goals of their projects.