Does Antibacterial Stainless Steel Really Work?

In today's health-conscious world, consumers and industries alike are increasingly seeking solutions that promise enhanced hygiene and protection against bacteria. This quest has led to the development and commercialization of antibacterial stainless steel, a material touted for its ability to inhibit bacterial growth. But does antibacterial stainless steel really work? To answer this question, it's important to explore how these materials function and analyze their efficacy in real-world applications.

Antibacterial stainless steel is designed to prevent the growth of bacteria through various mechanisms. Typically, it incorporates elements such as copper or silver, which are known for their antimicrobial properties. When bacteria come into contact with the surface of this enhanced stainless steel, these elements interfere with bacterial metabolism or disrupt cellular structures, ultimately leading to a reduction in bacterial colonies.

Real-World Applications and Efficacy of Antibacterial Stainless Steel

The effectiveness of antibacterial stainless steel is validated not just in laboratory settings but also in diverse real-world applications. Many healthcare facilities have embraced this material for surfaces and fixtures in an effort to minimize the risk of infections, as hospital environments are particularly susceptible to bacterial proliferation. Additionally, antibacterial stainless steel finds use in kitchens and food processing environments, where its ability to maintain cleanliness is paramount.

Antibacterial stainless steel shows promise in terms of its durability and effectiveness. However, it's worth noting that its performance may vary depending on specific conditions, such as humidity or exposure to certain cleaning agents. Continuous research and field studies strive to measure and enhance its efficacy, paving the way for broader adoption across various industries.

The Role of Span International in Advancing Material Safety

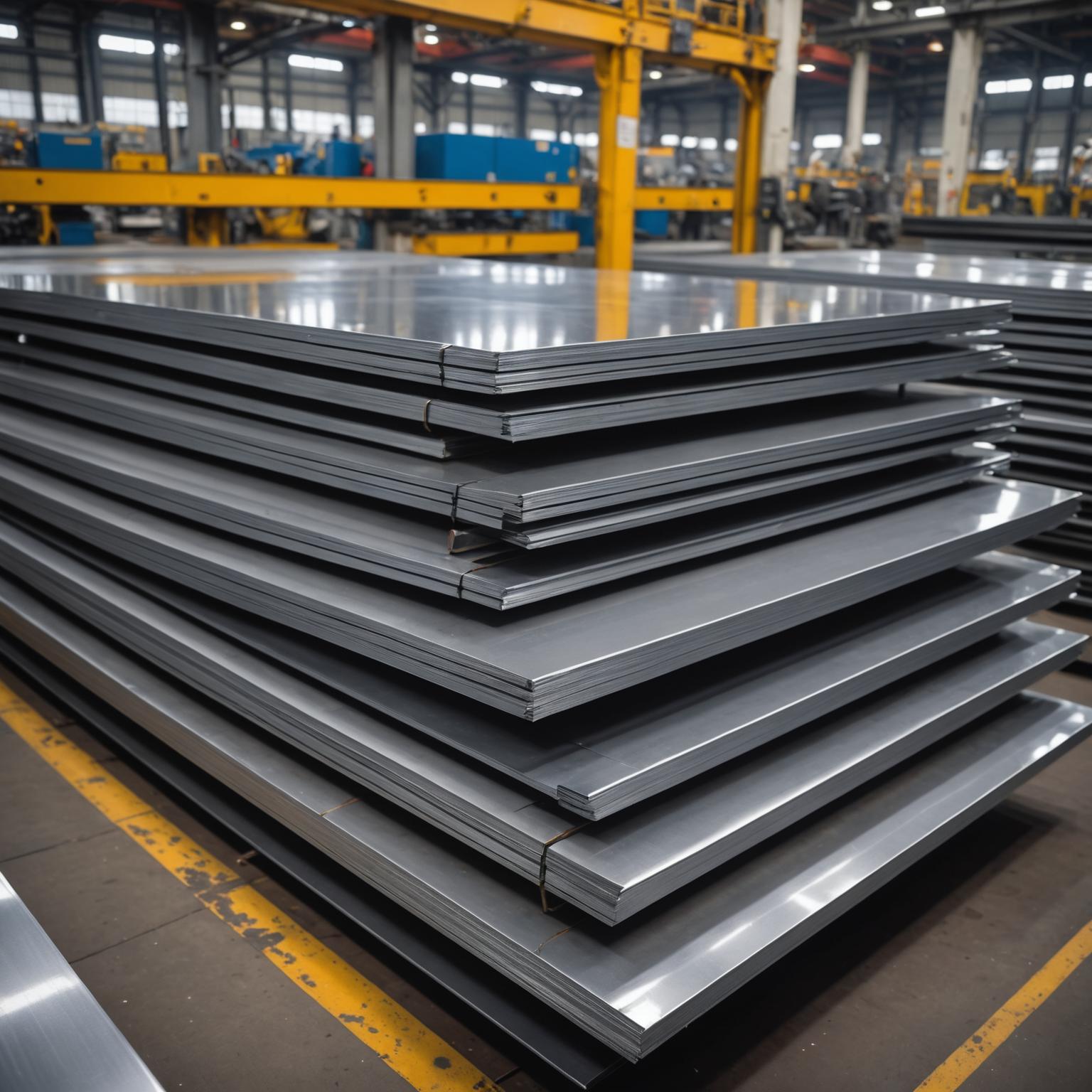

While antibacterial stainless steel is at the forefront of hygiene-enhancing materials, companies like Span International are constantly innovating in the field of material safety and performance. Their commitment to quality and sustainability is evident in their diverse product offerings. For example, the UltraMax Aluminum Sheets collection is engineered for exceptional structural integrity and longevity, ideal for applications requiring reliable and durable materials.

Span International's dedication to sustainability aligns with the growing demand for eco-conscious manufacturing processes. This focus on environmental responsibility ensures that their products, including aluminum composite panels, not only meet rigorous standards for sustainability but also contribute to reducing the environmental impact of industrial practices.

In summary, antibacterial stainless steel is an effective tool in the fight against bacterial contamination, and its role continues to expand across industries eager for improved hygiene solutions. With companies like Span International pushing the boundaries of material science, the future looks promising for advancements in antibacterial technologies and sustainable practices.