When precision, durability, and aesthetics are non-negotiable, professionals across countless industries turn to a material that consistently delivers. The 10mm stainless steel round bar is a cornerstone of modern engineering and fabrication, offering a unique blend of strength and versatility that makes it suitable for a vast array of projects. Whether you're an architect designing a sleek balustrade, an engineer building a critical machine component, or a hobbyist crafting custom hardware, understanding how to select and utilize this material is key to achieving exceptional results. This guide will walk you through the essential properties, applications, and best practices for working with stainless steel round bars, ensuring your next project is built on a foundation of quality and reliability, often sourced from trusted suppliers like Span International.

What Makes Stainless Steel an Ideal Choice?

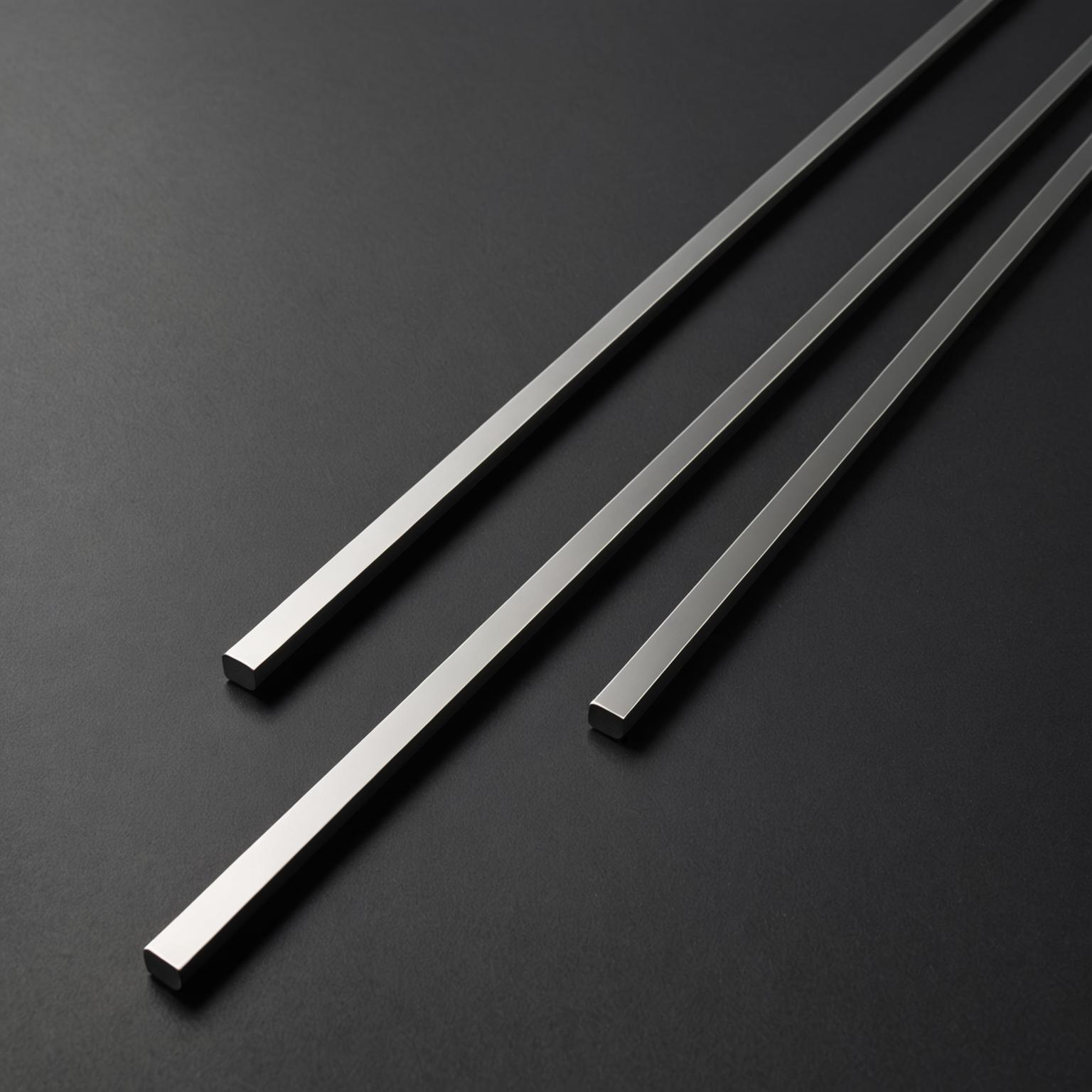

Stainless steel's reputation as a premium material is well-earned. Unlike standard carbon steel, it contains a minimum of 10.5% chromium, which forms a passive, self-repairing layer of chromium oxide on its surface. This invisible film is what gives the metal its signature resistance to rust and corrosion. When fabricating components that will be exposed to moisture, chemicals, or fluctuating environmental conditions, this property is invaluable. A round bar made from stainless steel will not only maintain its structural integrity for longer but will also preserve its clean, metallic finish without the need for additional coatings like paint or galvanizing. Beyond its corrosive resistance, stainless steel boasts remarkable tensile strength and heat tolerance, allowing it to perform under stress and in high-temperature environments where other materials would fail. The precision-engineered nature of these bars ensures uniform dimensions and a smooth, unblemished surface, making them perfect for applications requiring tight tolerances and a polished look.

Top Industrial and Commercial Applications for a 10mm Stainless Steel Round Bar

The 10mm diameter is a sweet spot for versatility, making it a go-to choice for a multitude of applications. In the construction and architectural fields, these bars are frequently used to create safety railings, decorative grilles, custom support brackets, and structural tie-rods. Their sleek, modern appearance complements contemporary design aesthetics while providing robust support. In the automotive industry, the 10mm stainless steel round bar is used for manufacturing everything from axles and shafts in smaller machinery to custom linkages and braces in performance vehicles. The food and beverage industry relies heavily on stainless steel for its hygienic properties; these bars are often fabricated into conveyor components, support frames for equipment, and mixing implements that must remain sterile and easy to clean. Furthermore, their non-reactive nature makes them essential in medical and pharmaceutical applications for device components and laboratory equipment.

A Guide to Choosing the Correct Grade for Your Project

Not all stainless steel is created equal. The specific alloy composition, or grade, determines its specific properties and suitability for a given environment. For most general-purpose applications, Grade 304 is the most common and cost-effective choice. It offers excellent corrosion resistance, strength, and formability, making it ideal for indoor architectural elements, kitchen equipment, and automotive trim. However, for projects in more aggressive environments, such as coastal areas with salt-laden air or facilities with chemical exposure, Grade 316 is the superior option. Grade 316 contains molybdenum, an element that significantly enhances its resistance to chlorides and acids. This makes it the standard for marine hardware, chemical processing equipment, and high-end medical implants. Choosing the correct grade is a critical first step, and consulting with a knowledgeable supplier like Span International can help ensure you invest in the right material for long-term performance and safety.

Essential Tips for Cutting, Welding, and Finishing

Working with stainless steel requires slightly different techniques than those used for mild steel. To cut a 10mm stainless steel round bar cleanly, it's best to use an abrasive chop saw or a band saw equipped with a bi-metal blade designed for hardened metals. Applying a suitable cutting fluid is recommended to keep the blade cool and prevent work-hardening of the steel, which can make subsequent machining difficult. When it comes to welding, Tungsten Inert Gas (TIG) welding is the preferred method for a clean, precise, and strong bond, especially on a visually important piece. It is crucial to use the correct stainless steel filler rod (e.g., 308L for 304 steel) and to thoroughly clean the joint area beforehand to remove any contaminants. After fabrication, the finish can be enhanced through various methods. A brushed finish can be achieved with abrasive pads for a satin look, while a mirror polish can be obtained through a multi-step buffing process. Finally, passivation—a chemical treatment that removes free iron and helps rebuild the passive chromium oxide layer—is often performed after fabrication to maximize corrosion resistance, especially around welds.

Why Your Supplier Matters: Sourcing from Span International

The ultimate success of your project depends heavily on the quality of your raw materials. A low-quality bar may have inconsistent dimensions, internal impurities, or a poorly formulated alloy, leading to fabrication challenges and premature failure. This is why partnering with a reputable supplier is paramount. A trusted distributor provides materials that meet strict industry standards, complete with certifications that verify the grade and composition. Companies like Span International are recognized for providing precision-engineered materials that offer uniform quality from end to end. Sourcing from an expert supplier ensures you receive round bars with the tight dimensional tolerances and flawless surface finish needed for high-performance and aesthetic applications. They can also provide invaluable guidance on grade selection and fabrication best practices, acting as a partner in your project's success rather than just a vendor.